CASE NATIONALE– NEDERLANDEN

SCOPE

PROJECT Renovation of the office space in the buildings Haagse Poort and Delftse Poort, including architectural modifications, interior walls, installation adjustments, custom-made furniture, flooring, and office layout.

INCENTIVE The implementation of new ways of working required a more dynamic work floor with different types of work environments.

PROJECT SIZE 37,000 sqm of office space

LOCATION Haagse Poort in The Hague (NL), floors 4 to 10

Delftse Poort in Rotterdam (NL), floors 6 to 16

TIME PERIOD 2019–2022

CIRCULAR AND SUSTAINABLE AMBITIONS The aspiration was to execute the renovation with zero waste and achieve 100% circularity. In pursuit of this, Nationale-Nederlanden aimed to establish clear objectives by making the process quantifiable. Furthermore, Nationale-Nederlanden sought to attain the highest WELL certification (platinum).

The design was premised on not starting from scratch but utilizing the prior interior as a foundation. Circularity was measured through a ranking system founded on the 10Rs, assessing the reuse and waste management of existing materials. This approach resulted in achieving an 89% level of circularity, conserving a total of 2722 tons of waste.

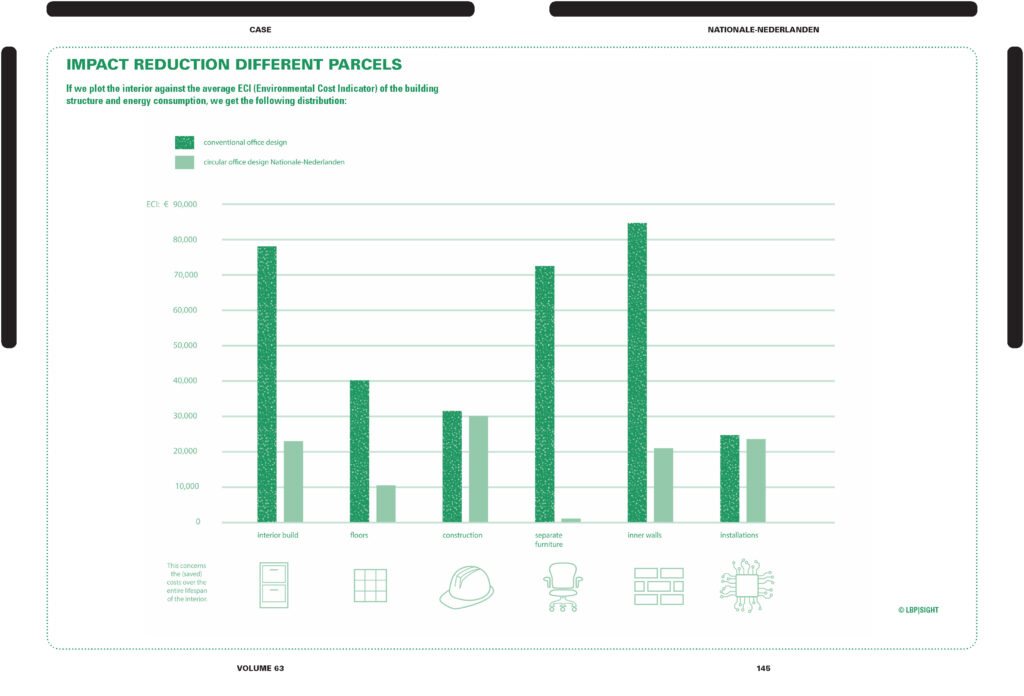

Furthermore, calculations were made to determine the environmental impact difference between a conventional project execution and the implementation of all the circular measures taken. This computation led to a significant 70% reduction in Environmental Impact (ECI).

STAKEHOLDER OVERVIEW

The following conversation with Gerwin Beukhof, interviewed by Marieke van den Heuvel, is part of an in-depth exploration of the circular renovation of the Nationale Nederlanden’s office spaces. From examining initial ambitions of 100% circularity and zero waste, to measurability issues, incentives, new ways of collaboration and the shifting position of the architect, the conversation with Gerwin Beukhof is assessing and reflecting on the projects impact.

Two lenses of the same pair of glasses

Gerwin Beukhof is a sustainability and environment consultant at LBP|SIGHT and explores calculating the impact.

GB: At LBP|SIGHT, circularity is one of my specialities. I mainly work with environmental impact measuring and lifecycle analyses (LCA). Together with my colleague, Jeannette Levels-Vermeer, we wrote a plan that put flesh on the circularity in Nationale-Nederlanden’s construction process. We set targets and thought about how to measure and account for them. Based on that, we made interim calculations, advised about the material properties, and calculated the total environmental impact of the project.

MvdH: What do you think of the result of a 70% reduction of the Environmental Cost Indicator (ECI) and 89% circularity?

GB: I think that a 70% ECI score is an enormous achievement and a direct result of the vast savings on materials. Nationale-Nederlanden started with a target of 100% circularity and 0% waste. We considered it a fantastic principle but also asked some counter questions right away. What would it be like? In the case of zero waste, everyone will imagine an empty skip, but what are the rules to achieving 100% circularity? Does that mean that no materials may be purchased? We suggested steering also on environmental impact since footprint reduction is the underlying objective of the circular economy.

MvdH: Could you explain what both scores are based on, starting with circularity?

GB: For the circularity index, we created a volume balance of the material flows and concluded that secondary materials were used for 89% of the renovation. That is a combination of reused materials or materials of secondary origins, so recycled.

MvdH: Which factors were included in the 70% ECI reduction?

GB: Among other factors, material use was linked to environmental impact. Because the more primary (new) materials can be saved, the fewer production processes must be started. For instance: If the frames of office chairs are used again, less steel produced by Tata Steel has to be used. The CO2 emissions you save can be deducted from the project’s environmental impact.

I mention CO2 emissions as they’re widely recognized, yet the ECI encompasses a broader spectrum of indicators. There’s also the depletion of abiotic base materials, which are the minerals and fossil fuels that come to an end and of which the exploitation is very harmful. There are nitrogen emissions, leading to a reduction of biodiversity. There’s acidification of the oceans, with all sorts of environmental consequences. There’s toxicity to humans, ecology and so on. All these factors are being added, and that determines the environmental cost. Those are the costs we, as a society, must pay for the project’s environmental impact. They are hidden costs, like the damages after a flooding or failing agriculture.

Those costs are not the same as the costs for neutralising the environmental effects. Unfortunately, taking one kilogram of CO2 out of the air costs much more, and these costs have not been calculated here.

MvdH: What’s the relationship between the two figures?

GB: We use circularity and ECI as two lenses of the same pair of glasses. We look through one lens at the renewability of the materials used and through the other at the environmental impact of those materials. I will give an example of how this may lead to quite different outcomes. The architects wanted to use wool for the furnishing of the sitting areas. Wool is a biobased material and, as such, is considered to be circular. A sheep produces new wool, and used wool is biodegradable. Woollen upholstery may seem like a good choice, but when we have a look at the impact, it is very high since it forms a part of intensive farming (meat production is a side product of wool). It is a relatively inefficient way to get yarn. Linking circularity to impact presents a good picture of the sustainability of products. In this project, we chose to use recycled wool only.

MvdH: Are all biobased products always seen as circular? And if so, is that also true for all the wood?

GB: We categorise biobased as circular since it is renewable. Biobased materials are part of the natural cycle in which the raw material can recover and the waste, in turn, becomes available as raw material. But that is not automatically the same for wood. New trees are not always planted, which is why we are dealing with deforestation worldwide. That is why we take a critical approach to sustainable forestry. Wood from those sources may be categorised partly as primary and partly as secondary material.

The same applies to some compound materials. For instance, a panel can be made from agricultural waste flows for 40% and newly material for 60%. In that case, we included the first part in the 89% circular score and the second part in the 11% non-circular score.

MvdH: You remained involved in the entire construction process. Did you act as a mirror for the builders?

GB: It was more of a steering mechanism than a mirror. We preferred to show the environmental impact of the proposed plans live at each meeting, but in the turmoil of the building process, that was not possible and actually a lot of work. However, in the case of significant decisions that involved large volumes of a specific material, we made interim calculations of the ECI savings of a particular choice.

MvdH: Was your involvement of significant influence on the result?

GB: Certainly, but there was also an important interaction: Our calculations gave direction and parties such as Fokkema & Partners, Superuse and Gielissen showed much creativity in finding alternative materials and solutions for reuse. We recalculated the solutions for a good underpinning of circularity.

Collaborating in this way was a new experience for us. We often only deal with the client, and we can select the materials based on their characteristics. Now we were in a team, together with the architects and the constructors, and were forced to think about the look and feel of materials as well.

MvdH: What would have been the difference for the project if you hadn’t intervened?

GB: This would have resulted in a greater variety of interior materials, potentially boasting compelling sustainability narratives, yet not inherently sustainable applications. The team introduced an array of novel materials, some circular or biobased, but necessitating supports that introduced their own environmental impact. Upon scrutinizing the Environmental Product Declarations (EPDs) of these products, the contrast in savings compared to conventional materials might prove minimal. In specific cases, the ecological footprint could even surpass that of the standard counterparts.

That was a pity since several of those materials have a lot of potential for the future, and that was the dilemma at the same time. On the one hand, we wanted to keep the ECI as low as possible, but we also wanted to apply more innovative products and help the suppliers increase their production. That is why in the case of the Event Space, together with Superuse, we expanded the criteria by including innovation and the underlying motivation when assessing the materials.

| An EPD, or Environmental Product Declaration, offers insights into the environmental impact of a product or material across its life cycle. To ensure transparency and enable meaningful product comparisons, EPDs must adhere to standardized methodologies and guidelines established by international bodies like the International Organization for Standardization (ISO) and European Standards EN 15804 and ISO 14025. Yet, an EPD’s reliability hinges on the accuracy of data presented by the manufacturer or creating organization. As such, independent verification by third-party experts is crucial to substantiate their credibility. |

MvdH: Which parcels scored particularly well?

GB: The furniture greatly affected the result since much of the existing furniture was refurbished. What certainly helped was that VEPA [Fair Furniture Group] wagered to give new guarantees for the life of the existing furniture. Our calculations include the extent of reuse, how long products last, and what maintenance is needed. Furthermore, we saved much on the inner walls. They had a high ‘R-rate’ for reuse since, with just a few adjustments, most of the walls could be given a second life.

MvdH: How can a better score be achieved in the future?

GB: The question is whether we can ever use something without environmental impact. In theory, perhaps, but it is still a long way to go. All cycles should be closed, and society should entirely rely on renewable energy without the need for mining.

If, under the current conditions, we want to decrease the environmental impact of a future project, it will lead to concessions on the programme of requirements and health. It is possible to steer more based on the availability of materials, but that could lead to a building that fits a little less. Or we could reuse more, but we were bound by the high quality that Nationale-Nederlanden aspires to for its work environment. They pursued a circular building and one that is as healthy as possible.

Complete access to the preceding conversations on Nationale Nederlanden’s project and more insights on circular interior design in VOLUME63, THE NOT-SO-EASY GUIDE TO CIRCULAR INTERIOR DESIGN.